In the dynamic world of commercial pressure washing, we wield powerful tools capable of erasing years of grime and revitalizing even the most weather-worn surfaces. Yet, amidst this transformational magic, it's vital to remember a fundamental truth: safety must always come first.

Picture this: a team of skilled pressure washing professionals, equipped with top-notch gear, meticulously restoring a commercial property to its former glory. It's a sight to behold, but what's not immediately evident is the careful planning, training, and adherence to safety protocols that underpin this operation.

In this article, we're delving into the crucial topic of safety in commercial pressure washing. We'll explore the best practices and essential guidelines that every contractor and operator should know. Whether you're a seasoned pro or just stepping into the high-pressure world of pressure washing, this guide is here to ensure that every job is not only brilliantly executed but also completely secure.

Let's embark on this journey to safeguarding both the integrity of our work and, most importantly, the well-being of every member of our team. After all, a pristine result is only truly satisfying when it's achieved without compromising safety.

Proper Equipment and Gear

When it comes to commercial pressure washing operations, the right equipment and gear are your first line of defense. Ensuring that you and your team are properly outfitted can make all the difference in maintaining a safe work environment.

A. Essential Safety Gear

Before even firing up the pressure washer, it's crucial to suit up in the appropriate safety gear.

This includes:

1. Protective Eyewear: Goggles or a face shield shield your eyes from water, debris, and chemicals that may be dislodged during the cleaning process.

2. **Gloves**: Choose chemical-resistant gloves to safeguard your hands from potentially hazardous detergents and sharp debris.

3. **Durable Footwear**: Non-slip, steel-toed boots provide stability and protect your feet from potential injuries.

4. **Ear Protection**: In high-pressure settings, pressure washers can generate significant noise. Earplugs or earmuffs are essential for protecting your hearing.

5. **Respiratory Protection**: Depending on the chemicals used, a respirator may be necessary to protect against fumes or vapors.

**B. Proper Equipment Selection and Maintenance**

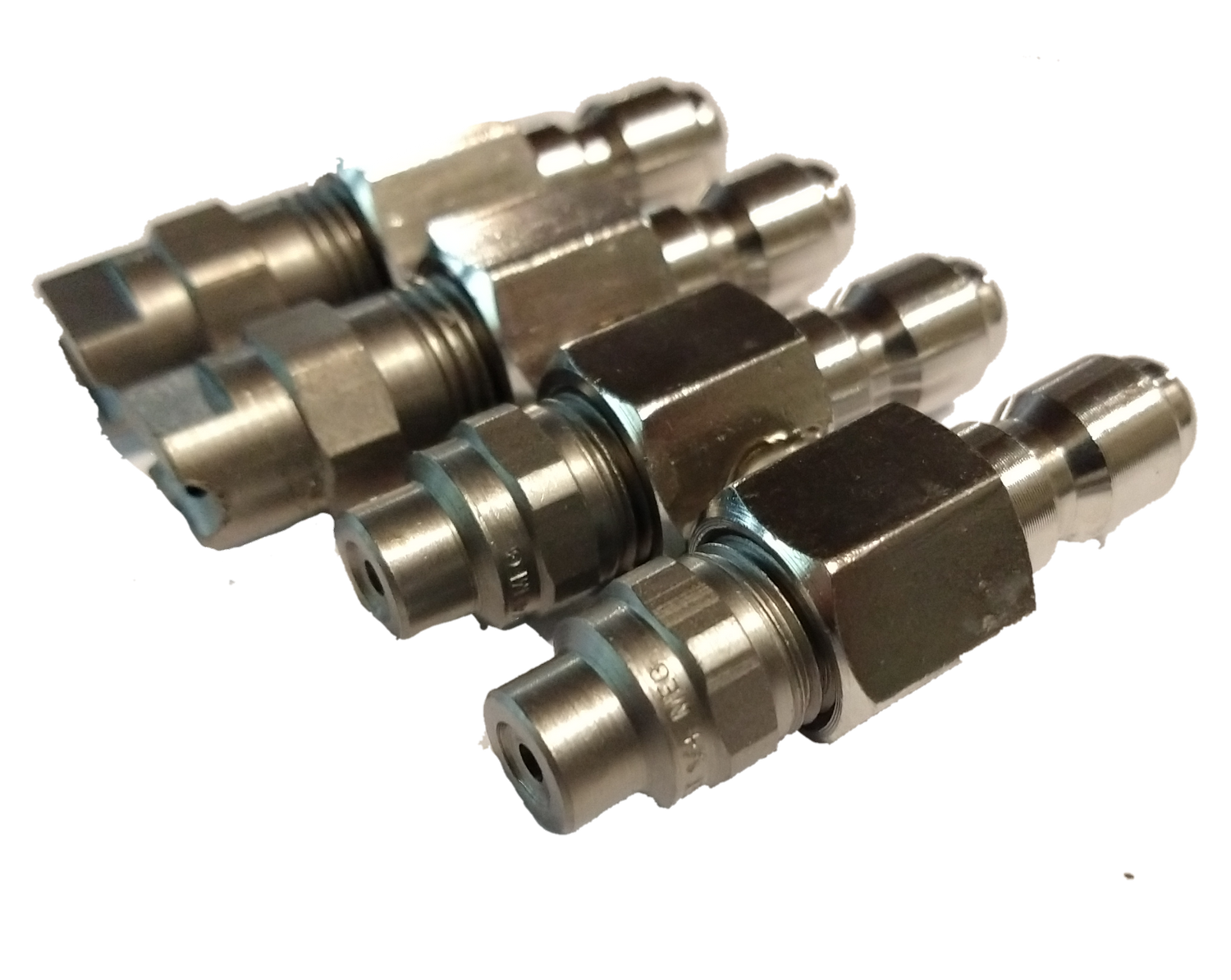

Selecting the right pressure washer for the job is a critical safety consideration. Ensure that the equipment is appropriately sized for the task at hand. High-pressure nozzles and attachments should also be inspected for any signs of wear or damage before use.

Regular maintenance is key to equipment longevity and safe operation. Check for leaks, ensure hoses and connections are secure, and inspect the trigger gun for any faults. It's a small investment of time that pays off in the form of uninterrupted, accident-free operation.

**C. Emergency Shutdown Procedures**

Every member of your team should be well-versed in emergency shutdown procedures. This includes knowing how to quickly and safely power down the pressure washer in the event of a malfunction or unexpected hazard.

By equipping your team with the right gear and maintaining your equipment diligently, you're setting the foundation for a safe and successful commercial pressure washing operation.

In the next section, we'll delve into the importance of a thorough site evaluation and preparation. Remember, safety starts with the basics!

**Section II: Site Evaluation and Preparation**

Before unleashing the power of a pressure washer, it's imperative to conduct a thorough site evaluation. This critical step ensures that potential hazards are identified and mitigated, setting the stage for a safe and effective pressure washing operation.

**A. Assessing Potential Hazards**

1. **Electrical Outlets and Wiring**: Identify the locations of electrical outlets and ensure they are properly covered and protected to prevent water damage or electrocution hazards.

2. **Fragile Surfaces**: Take note of any delicate materials or surfaces that may be susceptible to damage from high-pressure water. These may include delicate paintwork, wood, or fragile landscaping elements.

3. **Obstacles and Tripping Hazards**: Clear the area of any debris, tools, or equipment that could pose a tripping hazard to workers.

4. **Overhead Obstructions**: Be aware of any overhead structures or objects that may impede the safe operation of the pressure washer.

**B. Establishing Safety Zones**

Define specific areas where workers and bystanders should and should not be during the pressure washing operation. Clearly mark off these zones to prevent unauthorized access and ensure everyone's safety.

**C. Securing Loose Items**

Before beginning the pressure washing process, secure or remove any loose items in the vicinity. This includes items like outdoor furniture, signage, or loose debris that could become projectiles under the force of the pressure washer.

**D. Weather Considerations**

Be mindful of weather conditions. Windy conditions can make it more challenging to control the direction of the pressure spray and may pose additional safety risks.

Similarly, avoid operating in extreme weather conditions like heavy rain or lightning storms.

**E. Preparing Surfaces for Cleaning**

Pre-cleaning is a crucial step in preparing surfaces for pressure washing. This may involve sweeping or using a blower to remove loose debris, ensuring a more effective and efficient cleaning process.

By conducting a thorough site evaluation and taking the necessary precautions, you're setting the stage for a safe and successful commercial pressure washing operation. In the next section, we'll delve into the proper techniques and angles for effective pressure washing. Remember, a well-prepared site is the cornerstone of a safe work environment!

**Section III: Proper Techniques and Angles**

Once the site is properly evaluated and prepared, it's time to focus on the actual pressure washing process. Understanding the correct techniques and angles is essential for achieving optimal results while ensuring the safety of both the operators and the surfaces being cleaned.

**A. Angles for Effective Cleaning**

1. **Maintain a 45-Degree Angle**: Hold the pressure washer nozzle at a 45-degree angle to the surface being cleaned. This angle strikes a balance between removing dirt and grime without causing damage.

2. **Avoid Direct Angles on Delicate Surfaces**: When dealing with more delicate materials, like wood or painted surfaces, it's best to approach at a shallower angle to minimize the risk of damage.

3. **Use a Fan Spray Pattern**: Opt for a fan spray pattern rather than a concentrated jet stream. This distributes the pressure more evenly, reducing the risk of gouging or etching surfaces.

**B. Keep a Safe Distance**

Maintain a safe distance between the pressure washer nozzle and the surface being cleaned. This distance varies depending on the pressure and type of nozzle being used, but a general guideline is to start around 2-3 feet and adjust as needed.

**C. Avoid High Pressure on Fragile Surfaces**

Exercise caution when pressure washing more delicate surfaces. Lower the pressure and use a wider spray pattern to minimize the risk of causing damage.

**D. Continuous Motion**

Avoid concentrating the pressure washer on one spot for too long. Keep the nozzle in motion to ensure even cleaning and prevent any potential damage from excessive pressure in a single area.

**E. Test in an Inconspicuous Area**

Before starting a large-scale pressure washing job, it's advisable to perform a test in a less noticeable area to gauge the effectiveness and ensure no damage occurs.

By adhering to these proper techniques and angles, you'll achieve thorough and effective cleaning results while minimizing the risk of unintended damage. In the next section, we'll explore the importance of chemical safety and environmental considerations in commercial pressure washing operations. Remember, precision and caution are key!

**Section IV: Chemical Safety and Environmental Considerations**

In commercial pressure washing, the choice and handling of cleaning agents and detergents play a pivotal role in achieving a thorough clean. However, it's equally crucial to prioritize safety and environmental consciousness when selecting and using these chemicals.

**A. Proper Handling and Storage**

1. **Follow Manufacturer Guidelines**: Always adhere to the manufacturer's recommendations for handling, diluting, and storing cleaning chemicals. This ensures both effectiveness and safety.

2. **Labeling and Identification**: Clearly label and identify all chemical containers. Store them in a secure, designated area away from direct sunlight and extreme temperatures.

3. **Avoid Mixing Chemicals**: Never mix different cleaning agents unless explicitly instructed by the manufacturer. Some combinations can produce harmful reactions.

**B. Eco-Friendly Alternatives**

Consider using environmentally-friendly detergents and cleaners whenever possible. These options are designed to minimize harm to the environment while still effectively removing dirt and grime.

**C. Containment and Runoff Management**

Take precautions to contain and manage runoff water, especially when working near storm drains, bodies of water, or sensitive environmental areas. Use barriers or diversion methods to prevent chemicals from entering the natural ecosystem.

**D. Disposal of Chemicals**

Dispose of chemicals according to local regulations and guidelines. Many areas have specific protocols for the proper disposal of cleaning agents, so be sure to follow them diligently.

**E. Protecting Plants and Landscaping**

Before applying chemicals, take measures to protect plants, landscaping, and grass from potential harm. Covering them with plastic or wetting them thoroughly beforehand can help prevent damage.

By prioritizing chemical safety and environmental considerations, you not only ensure the safety of your team but also contribute to a more sustainable and eco-conscious approach to commercial pressure washing. In the next section, we'll cover electrical safety and power management, rounding out the comprehensive approach to safety in pressure washing operations. Remember, a clean environment starts with responsible practices!

**Section V: Electrical Safety and Power Management**

In commercial pressure washing, the safe use of electricity is paramount. Operating pressure washers near electrical sources requires careful attention to prevent potential hazards. Here, we'll cover important guidelines to ensure electrical safety on the job.

**A. Outdoor Outlets and GFCIs**

1. **Use Outdoor-Rated Outlets**: Ensure that the power source you're using is rated for outdoor use and properly grounded.

2. **Ground Fault Circuit Interrupters (GFCIs)**: Use outlets equipped with GFCIs, which are designed to automatically shut off power in the event of a ground fault, providing an extra layer of protection.

**B. Extension Cords and Outlets**

1. **Heavy-Duty Extension Cords**: Use heavy-duty extension cords designed for outdoor use and appropriate for the power requirements of your pressure washer.

2. **Avoid Overloading Circuits**: Do not overload outlets or circuits by plugging in multiple high-powered devices simultaneously.

**C. Equipment Inspections**

Regularly inspect all electrical components of your pressure washer, including cords, plugs, and outlets, for signs of wear, damage, or fraying. Replace any damaged components immediately.

**D. Weather Considerations**

1. **Avoid Wet Conditions**: Refrain from operating electrical equipment in wet conditions to prevent the risk of electrical shock.

2. **Use Weatherproof Covers**: When working in outdoor environments, utilize weatherproof covers to protect electrical outlets and connections.

**E. Safe Practices for Power Cords**

1. **Position Cords Carefully**: Keep power cords away from areas where they might be tripped over or come into contact with water.

2. **Avoid Pinching or Crushing**: Ensure that cords are not pinched or crushed by heavy equipment, which can damage the insulation and pose electrical risks.

By following these electrical safety guidelines, you'll create a secure working environment, reducing the risk of electrical hazards during commercial pressure washing operations. In the next section, we'll focus on fall protection and working at heights, addressing additional safety considerations for elevated surfaces.

Remember, vigilance and caution around electricity are non-negotiable!

**Section VI: Fall Protection and Working at Heights**

In some commercial pressure washing scenarios, working at elevated heights is unavoidable. Whether it's cleaning multi-story buildings or high outdoor structures, implementing proper fall protection measures is crucial to ensure the safety of your team.

**A. Fall Protection Equipment**

1. **Safety Harnesses**: Provide and ensure the proper use of safety harnesses for anyone working at elevated heights. These should be correctly fitted and securely anchored.

2. **Lanyards and Lifelines**: Utilize lanyards and lifelines to provide additional support and prevent falls. They should be attached to secure anchor points.

**B. Scaffolding and Elevated Platforms**

1. **Sturdy Construction**: Ensure that any scaffolding or elevated platforms are constructed and maintained to industry safety standards.

2. **Regular Inspections**: Conduct thorough inspections before each use to identify any potential weaknesses or hazards.

**C. Proper Ladder Usage**

1. **Select the Right Ladder**: Choose a ladder of appropriate height and weight capacity for the task. Ensure it's in good condition without any defects.

2. **Stable Placement**: Set up the ladder on a stable, flat surface, and use leveling devices if necessary.

**D. Guardrails and Edge Protection**

Install guardrails or edge protection systems on elevated surfaces to prevent accidental falls. These safeguards should be securely attached and properly maintained.

**E. Training and Certification**

Ensure that all team members working at heights receive proper training in fall protection techniques. Certifications in working at heights may be required in some regions.

By implementing these fall protection measures, you're taking crucial steps to safeguard the well-being of your team members when working at elevated heights. In the next section, we'll address emergency response and first aid protocols, ensuring that you're prepared to handle any unexpected situations on the job. Remember, safety should always be a top priority!

**Section VII: Emergency Response and First Aid**

In any work environment, it's essential to be prepared for unexpected situations or accidents. Commercial pressure washing is no exception. Having a well-defined emergency response plan and access to basic first aid supplies can make a significant difference in handling unforeseen events.

**A. Emergency Response Plan**

1. **Clear Communication**: Establish a clear communication protocol for alerting team members in the event of an emergency. Ensure everyone knows how to contact emergency services.

2. **Evacuation Routes**: Identify and communicate evacuation routes from the work area. Designate meeting points for accountability.

3. **Emergency Contacts**: Maintain a list of emergency contact numbers, including local emergency services, nearby hospitals, and relevant company contacts.

**B. First Aid Kit**

1. **Accessible Location**: Keep a well-equipped first aid kit easily accessible on-site. Ensure all team members know its location.

2. **Basic Supplies**: The first aid kit should include essentials such as bandages, antiseptics, adhesive tape, scissors, tweezers, and gloves.

**C. CPR and Basic Life Support Training**

Encourage team members to undergo CPR (Cardiopulmonary Resuscitation) and basic life support training. Knowing how to respond in a medical emergency can be lifesaving.

**D. Reporting Procedures**

Establish clear procedures for reporting accidents or injuries. Encourage prompt reporting to ensure that appropriate action can be taken swiftly.

**E. Hazard Recognition and Prevention**

Train team members to recognize potential hazards and take steps to prevent accidents before they occur. This proactive approach can help minimize the likelihood of emergencies.

**F. Mock Drills and Scenario Training**

Conduct mock drills to practice emergency response procedures. Simulate various scenarios to ensure that team members are familiar with what to do in different situations.

By having a well-prepared emergency response plan and access to basic first aid supplies, you're equipping your team to handle unforeseen events with confidence and efficiency.

In the next section, we'll wrap up our comprehensive guide by emphasizing the importance of ongoing training and continuous education in maintaining a safe work environment. Remember, preparedness can make all the difference!

**Section VIII: Training and Continuous Education**

In the ever-evolving field of commercial pressure washing, staying updated on best practices, industry trends, and safety protocols is crucial. Providing ongoing training and encouraging continuous education not only enhances the skills of your team but also reinforces a culture of safety.

**A. The Value of Ongoing Training**

1. **Equipment Familiarization**: Ensure that all team members are well-versed in the operation and maintenance of pressure washing equipment.

2. **Safety Protocols**: Regularly review and reinforce safety protocols to keep them fresh in the minds of your team.

**B. Certifications and Accreditation**

Encourage team members to pursue relevant certifications and accreditation in commercial pressure washing. These credentials demonstrate a commitment to professionalism and safety.

**C. Industry Workshops and Seminars**

Attend industry workshops and seminars to stay updated on the latest technologies, techniques, and safety standards in commercial pressure washing.

**D. Cross-Training Opportunities**

Provide opportunities for cross-training within your team. This not only broadens skill sets but also fosters a collaborative and safety-conscious work environment.

**E. Toolbox Talks and Safety Meetings**

Conduct regular toolbox talks and safety meetings to address specific safety concerns, share best practices, and provide a forum for open discussion.

**F. Safety Audits and Reviews**

Periodically conduct safety audits and reviews to identify areas for improvement and ensure that safety measures are effectively implemented.

By prioritizing training and continuous education, you're not only investing in the growth and development of your team but also reinforcing a safety-first culture within your organization. This proactive approach contributes to a safer and more efficient work environment.

In conclusion, remember that safety is a shared responsibility and a commitment that pays off in the form of a secure and successful commercial pressure washing operation.

**Section IX: Conclusion: Upholding Safety as a Priority**

As we conclude this comprehensive guide to safety in commercial pressure washing operations, it's essential to reflect on the paramount importance of placing safety at the forefront of every task and decision. The success of any pressure washing endeavor hinges on the well-being of your team and the integrity of your work.

By meticulously following best practices, from equipping your team with the right gear to conducting thorough site evaluations, and from implementing proper techniques to prioritizing chemical safety and environmental consciousness, you're not only ensuring a safe work environment but also guaranteeing exceptional results.

Remember, safety is a collective effort. It requires vigilance, continuous education, and a steadfast commitment from every member of your team.

Through ongoing training, certifications, and a proactive approach to hazard prevention, you're not only safeguarding your team members but also elevating the standards of your operation.

In the dynamic world of commercial pressure washing, where power meets precision, let safety be the unyielding foundation upon which your success is built. By upholding safety as a priority, you're not just achieving clean surfaces; you're cultivating a culture of excellence and responsibility.

As you embark on your pressure washing endeavors, may each spray of water be a testament to the dedication and care you invest in your team's safety. Through these collective efforts, we forge a path towards a safer, more prosperous industry, one clean surface at a time. Remember, safety isn't just a practice – it's a promise.

**Section X: Call to Action**

As you embark on your commercial pressure washing ventures, it's essential to put safety first. By implementing the best practices outlined in this guide, you're not only ensuring the well-being of your team but also setting the stage for exceptional results.

Now, it's time to take action. Here are some steps you can follow to prioritize safety in your commercial pressure washing operations:

1. **Conduct a Safety Assessment**: Review your current safety protocols and identify areas for improvement.

2. **Provide Ongoing Training**: Offer regular training sessions to keep your team updated on the latest safety practices and techniques.

3. **Invest in Proper Equipment**: Ensure your team has access to high-quality, well-maintained pressure washing equipment and safety gear.

4. **Encourage Certification and Accreditation**: Support your team members in obtaining relevant certifications and accreditations in commercial pressure washing.

5. **Establish an Emergency Response Plan**: Create a clear and actionable plan for responding to emergencies or accidents.

6. **Promote a Safety-Conscious Culture**: Foster an environment where safety is a shared responsibility and a top priority.

7. **Stay Informed and Educated**: Keep up with industry trends, attend workshops, and seek opportunities for continuous learning.

Remember, safety isn't just a checklist—it's a commitment to the well-being of your team and the quality of your work. By embracing a safety-first mindset, you're not only protecting lives but also ensuring the success and longevity of your commercial pressure washing operation. Here's to safe and successful ventures!