All about downstream injectors!

This segment will be focusing on downstream injectors, downstream injector kits, repairing a downstream injector, and how to use a downstream injector in combination with a JROD.

Don't forget to check back on 2/15/21 for our next segment talking about free and low cost marketing ideas for new businesses!

What is a downstream injector?

A downstream injector is a device used to inject chemicals or detergent into the flow of water after the pump on your pressure washer. This differs from an upstream injector which injects chemical before the pump. By using the downstream injector you are able to safely add fairly harsh chemicals or detergents into your water flow at a lower pressure to aid in cleaning power without the risk of damaging your pressure washer pump.

How does the downstream injector work?

When a low pressure situation is created in the system by using a larger nozzle the injector uses the Venturi effect to create suction through the inlet barb. If pressure increases the suction will stop and the system will continue to work as normal.

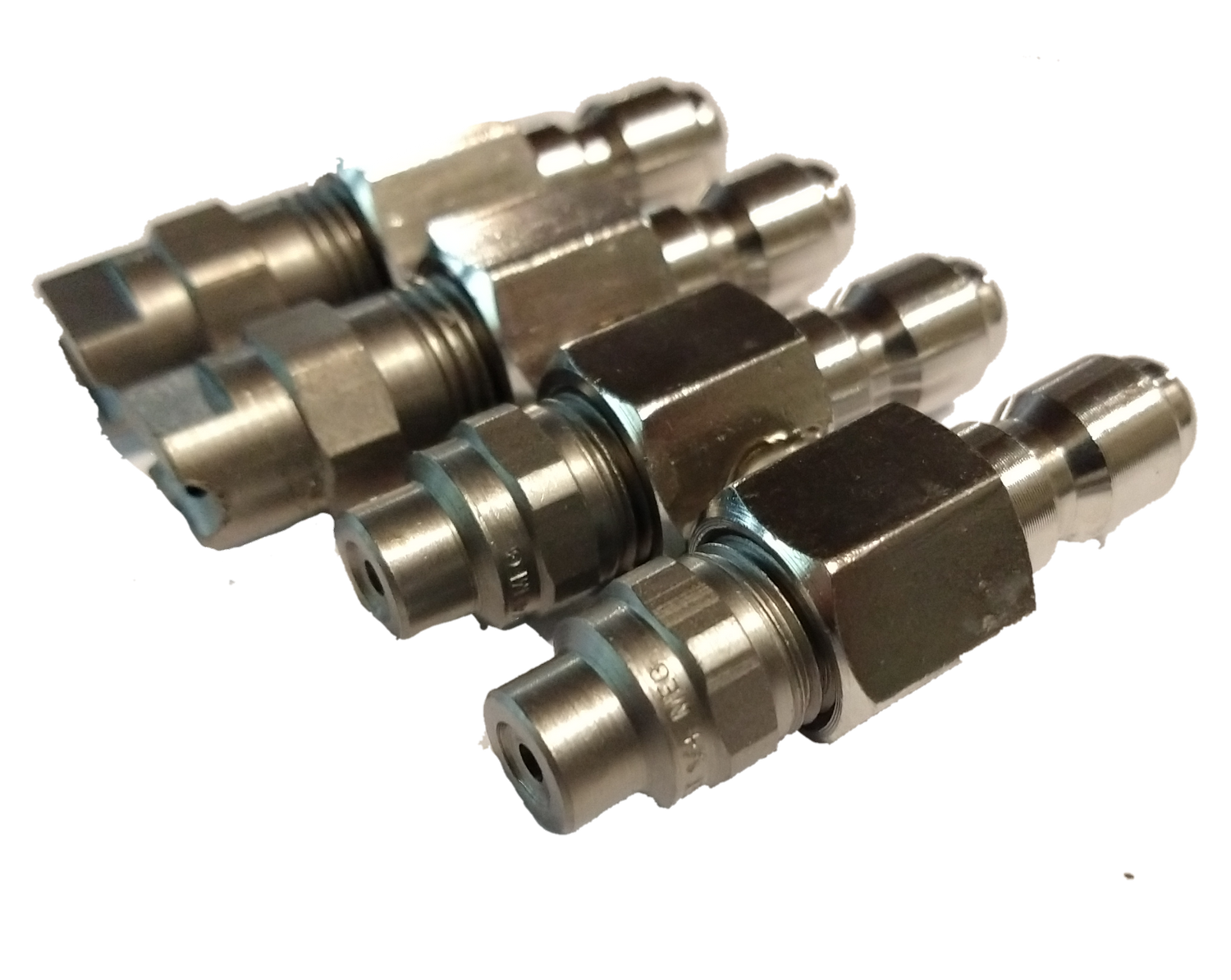

What is a downstream injector kit?

A downstream injector kit usually includes the downstream injector, the inlet hose, an inlet strainer or filter, and the necessary quick couplers to connect it into your system.

How to use a downstream injector with a JROD

Many customers pair a downstream injector or injector kit with a JROD nozzle kit (available here). The JROD includes nozzles sized appropriately for downstreaming with 2 nozzles that will not draw chemical allowing for rinsing and 2 nozzles that will draw chemical for washing. This not only saves time and boosts productivity by having the nozzles all connected in one easy to use fitting it also completely prevents the need for ladders on many homes.

How to troubleshoot and repair a downstream injector

Due to the simple nature of the downstream injector and it's operation it is also very simple to test and repair. There are two main issue you may experience that we will discuss here; how to fix a downstream injector that won't draw soap, and how to fix a downstream injector that won't stop drawing soap.

1) What to do if your downstream injector won't draw soap or chemical:

First check to make sure the size of your injector matches the size of your machine. Usually size 1.8 is good for 2-3GPM machines, size 2.1 is good for 3-5GPM machines, and 2.3 is good for 6-8GPM machines.

If this all lines up then next you need to check your nozzle size. 3-5GPM machines will need a 30-40 orifice size nozzle in order to draw soap. 8GPM machines will need a 40-60 orifice size nozzle. Using nozzle sizes too small will create too much pressure for the Venturi effect to start and the suction to take place. You can test this by using no nozzle and checking for flow of soap.

If neither of these steps appear to work you can check hose length. Usually injectors will pull chemical fine at hose lengths of 200' and sometimes out to 250' without issue but a safe bet is a hose length between 150'-200'. Once you exceed that you are exponentially increasing the likelihood that you will have draw issues at some point.

After checking these items the next place to look would be any air or water leaks in the system where your connections are made. These can change the pressure in the system and prevent the injector from functioning correctly.

Once you have confirmed the system is all in working order it is possible you have a stuck check ball in your injector. After chemical use and allowing the injector to sit for extended periods the ball may seize in the barb of the injector preventing flow. You can remove the inlet hose and take a small object such as an ORING repair pick (available here) and press into the opening of the barb. You should feel a ball there which can be easily depressed and will spring back up into place with little to no force.

If you have found the ball is stuck or it still doesn't function the next step is to remove the barb itself from the injector. Be cautious when doing this as there is a very small spring and ball inside. The ball should be clean and free of rust and corrosion. The area inside the barb where it seals should be clean and free of debris. You can soak the injector, ball, spring, and barb in household cleaning vinegar for a few hours to clean any mineral deposits or rust from the inside of it. Once this has been well cleaned you can either assemble it as it is and check it's operation again or you can purchase an injector rebuild kit (available here) that will include a ceramic ball to prevent the corrosion issues associated with the stainless steel ball included in most injectors.

Assembly should be in the reverse order of removal making sure the ball goes into the barb towards the hose then the spring will follow it.

2) What to do if your injector won't stop drawing soap?

This is usually caused by an injector that is sized too small for your machine. Please refer to the sizing listed above to make sure your injector is sized correctly. If this is not the problem then you are using too large of nozzle which has lowered your pressure too much.

Below you can find links to our recommended downstream injector, downstream injector kits, and JRODs.

Downstream injector

Downstream injector kit

https://pressurecity.com/collections/injectors/products/downstream-injector-kit

JROD

https://pressurecity.com/products/4-nozzle-kit-with-nozzle-holder?_pos=1&_sid=c6f0c1a3f&_ss=r